Powkeen Hard-Tools Co. Ltd

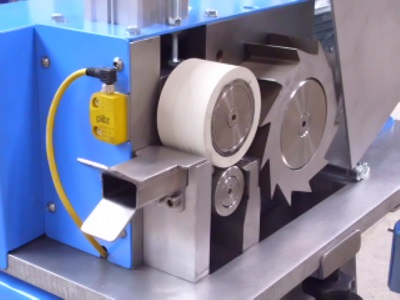

Model 750-1 Pelletizer

Automatic Machining Solutions

A technical sales agency representing some of the most advanced quality manufacturers of production extrusion, pelletizing and size reduction machinery, accessories and instrumentation for precision manufacturing in the plastics and rubber industries.

Model 800 Series Suction Dryer

BM-15 HD Labortory Pelletizer

TGW International Precision Knives

Model 750 Integral Pelletizer

Ceramic Knives and Pelletizer Rotors

Precision Industrial Knives for strand pelletizers, die face pelletizer , granulators and shredders .

Strand Pelletizer knives for Accrapak, Automatik, Bay Plastics, Conair, Cumberland, Rieter, and Sheerbay.

Die Face Pelletizer knives for Beringer, Dynisco, Erema, Gala and Nordson.

Shredder knives for Barclay, CM Shredders, Shred-Tech, Vecoplan and Granutech-Saturn Shredders.

600 DC Bagger Digital

ASL Series Pelletizer

Precision Drive Systems - (PDS)

Accrapak Systems Ltd

AMS represents Accrapak Systems Ltd - a quality manufacturer of strand pelletizers with associated down stream equipment. Additionally they provide suction dryers and weighing / bagging systems.

Accrapak Systems manufactures a broad range of pelletizers ranging from their production model ALS with an 150 mm wide feed managing 30 strands producing 1,600 Kg/hr (Sg 1.5) to laboratory unit model 750-1 with a 30 mm wide feed for 1 to strands producing 30 Kg/hr.

Plastics - Pelletizers, Granulators & Extruders

Packaging - Horizontal Form, Fill, Seal - Vertical Bagger

TGW International -

Industrial Machine Knives

Converting - Bag- Film - Corrugated

Processing - Poultry, Seafood and Beef

Printing - Pressrooms - Bindery

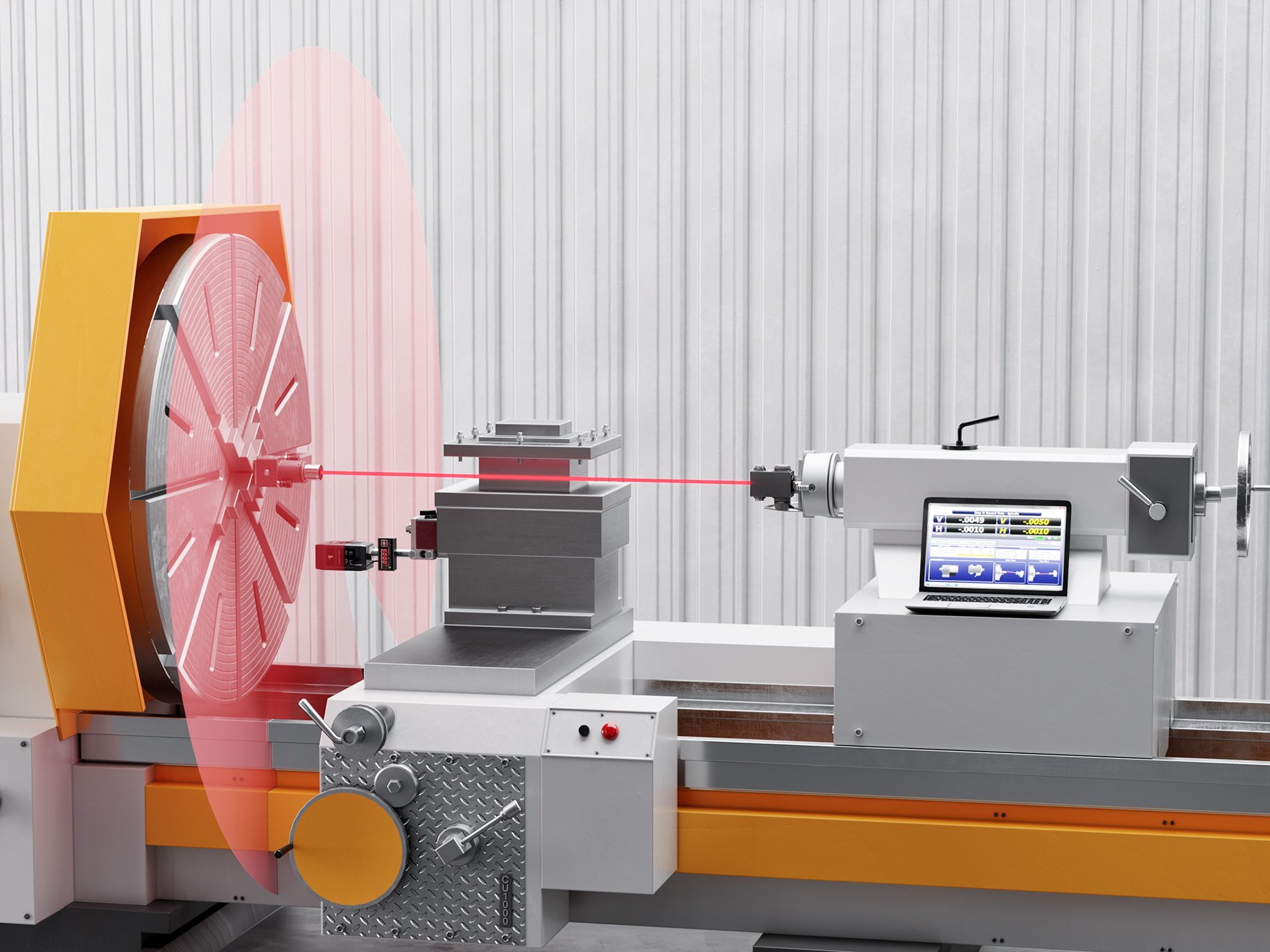

Hamar Laser Instruments -

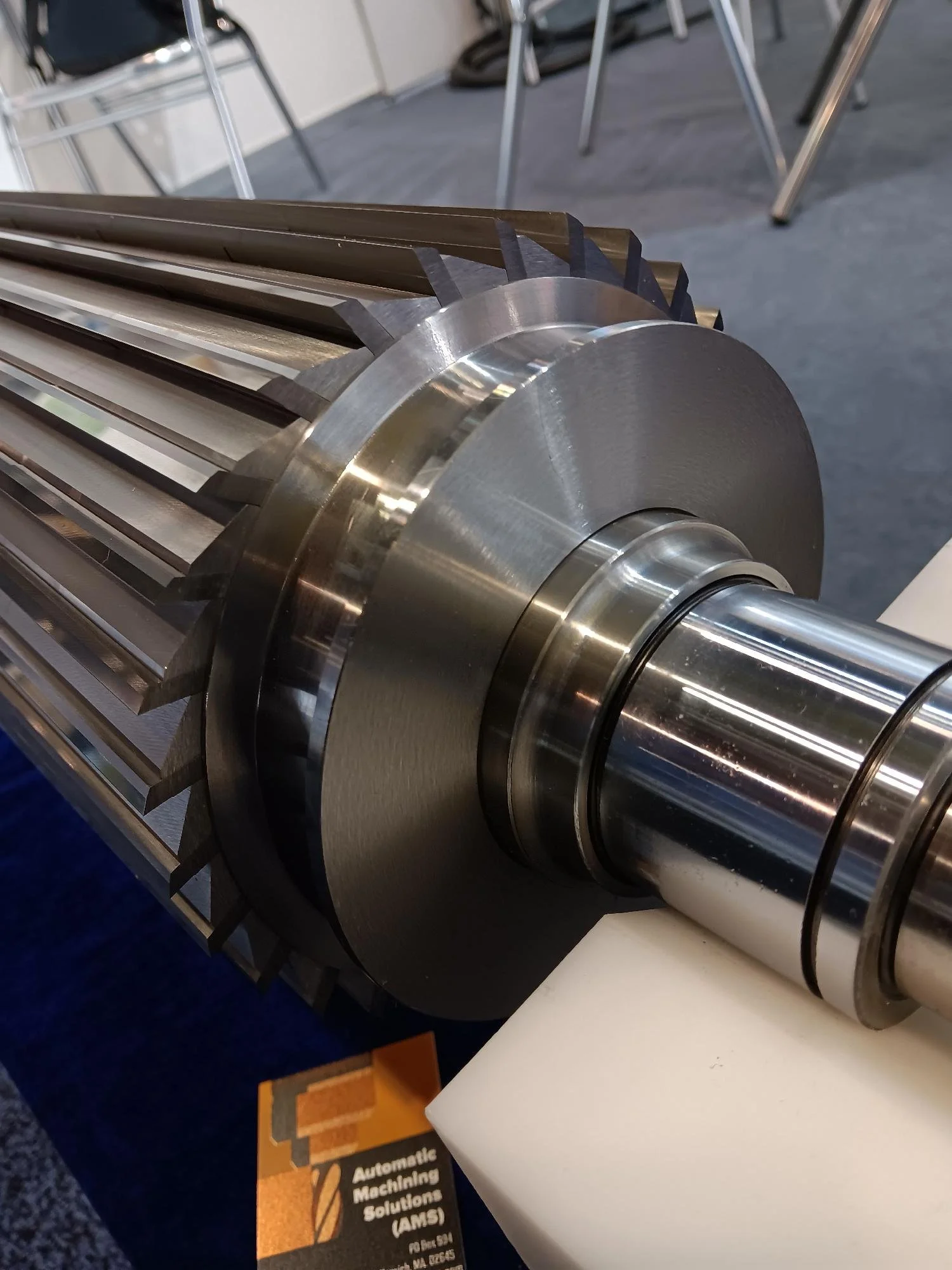

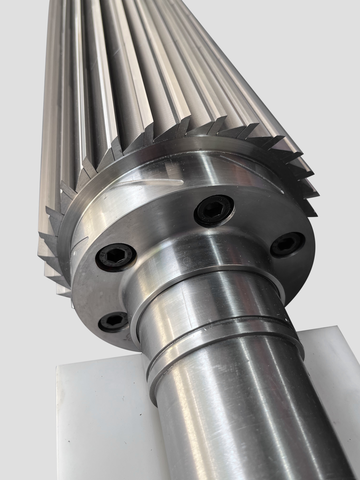

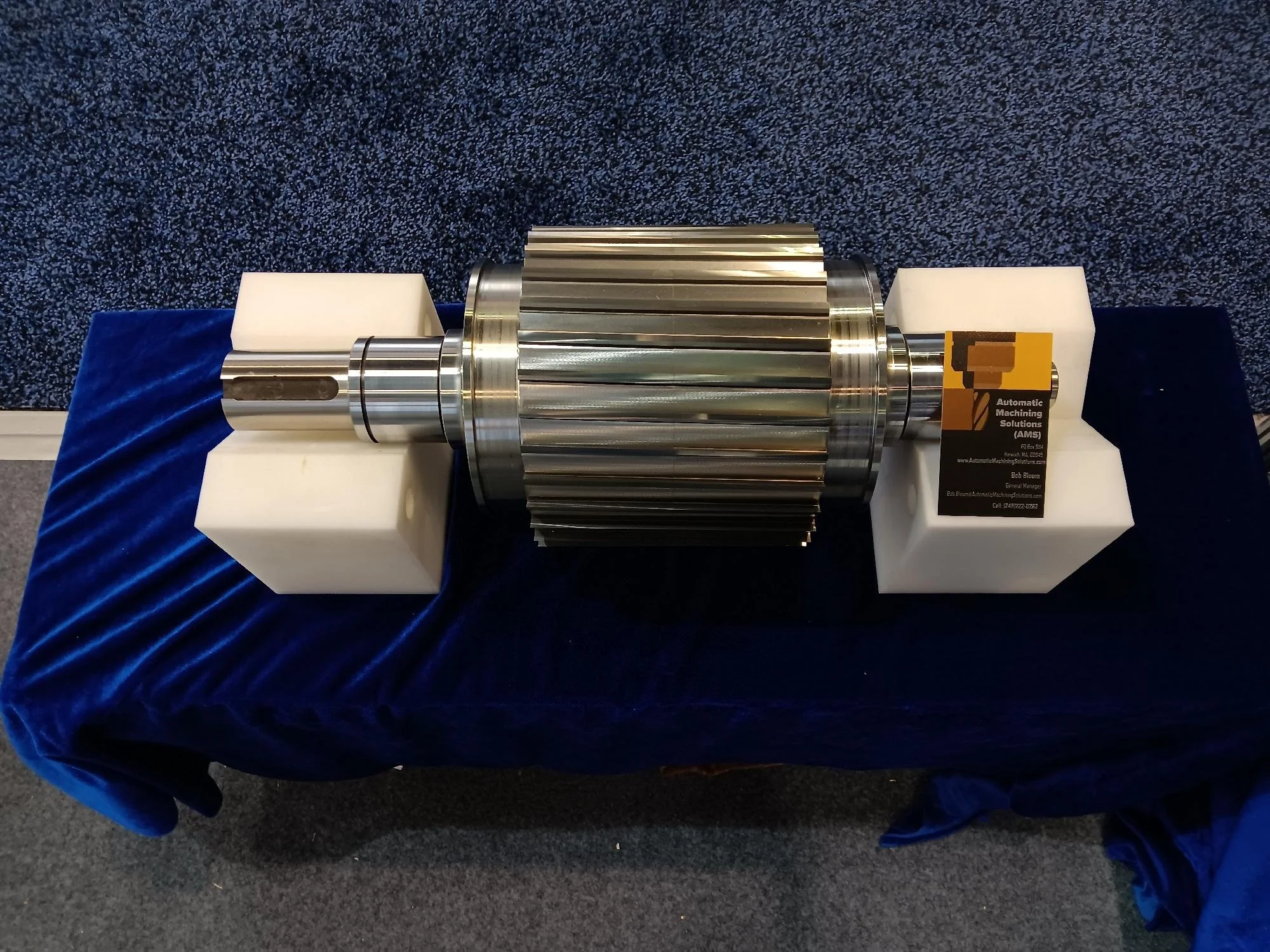

When Spindle Integrity Makes the Difference - Turn To Automatic Machining Solutions For Results.

Synchronette - Manufactured by FAS Machine

Make it stand out

Accrapak Systems Ltd - Pelletizers with downstream equipment, dryers, weighting and bagging machines

FAS Machine Tool - Sychronette Screw Machines

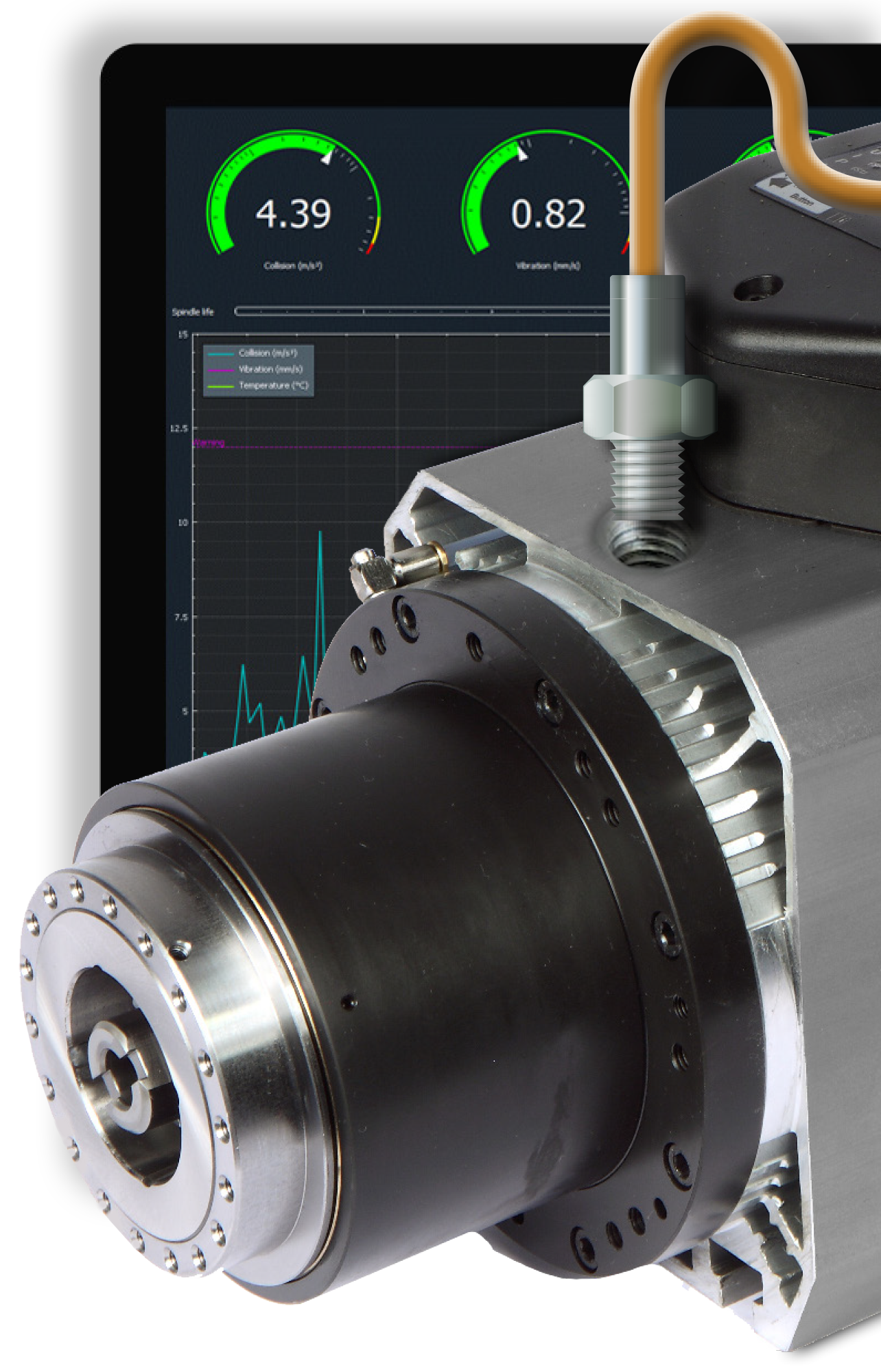

PDS Spindle Drive Systems

Hamar Lasers

TGW International - Precision Industrial Knives

Recondition Spindles

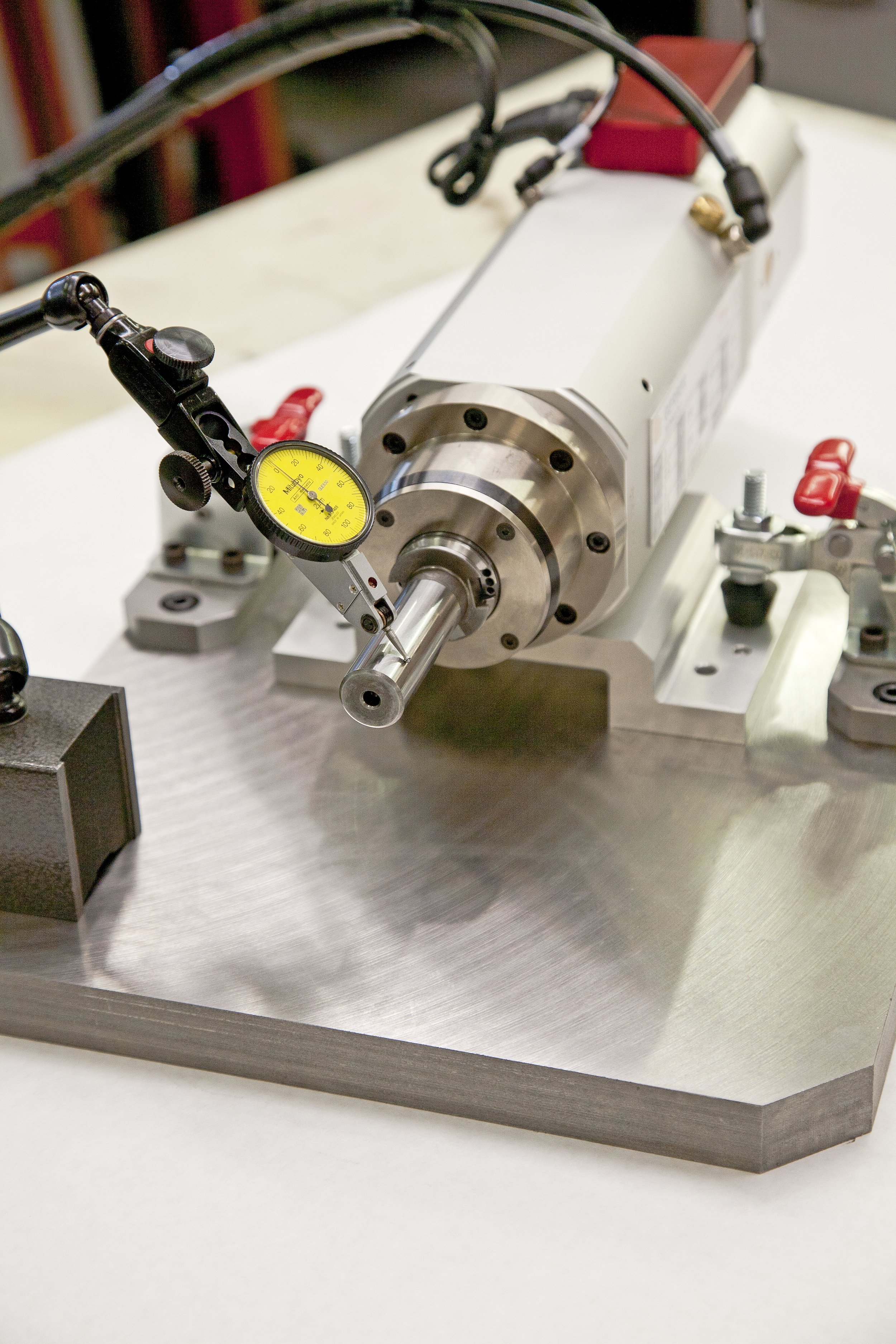

Every spindle is disassembled to core components, cleaned, inspected for wear/damage and a detailed report is generated providing a detailed planned procedure to recondition and return to original OEM standards or improved to your specifications. All reconditioned spindles are assembled in a clean room, tested for a minimum of (4) four hours with vibration and thermal monitoring to confirm integrity. All results are documented. All reconditioned spindles are warranted for (1) year.

Contact Automatic Machining Solutions at (248) 722-0262

-

All reconditioned spindles meet or exceed OEM specifications.

-

The Best Protection in the Industry.

-

-

Item description

Full Service Capabilities

-

Spindle Repair

All spindles are returned to OEM specifications and covered with a (1) one year warranty.

-

Spindle Replacement

Many spindle models are stocked for rapid change out and prevention of lost production.

-

Spindle Monitoring Systems

Health Monitoring System that identifies issues before they cause down time and unnecessary repair cost - Integral Preventative Maintenance

-

Tooling

Complete tooling accessories

Call (248) 722-0262 or send us an inquiry with the form to the right.

Tell us how we can help!

Please send us an email and advise how we can help. We are pleased to provide a quotation for a spindle or any related component. Also, we can assist with technical issues. Please complete the following form with information requested and we will promptly respond to your inquiry.

Precision Spindle Technology For All Industries

Automatic Machining Solutions (AMS) is a non-exclusive sales representative in the New England area, New York, New Jersey and Pennsylvania for PDS - Precision Drive Systems of Bessemer City - North Carolina.

We offer greater than 50 years of experienced in applications, set-up, operation, trouble shooting, repair/reconditioning and process improvement in metal turning, boring and grinding of precision critical parts in the machine tool industry.

For additional information on spindle related products and services - Please contact Bob Bloom/General Manager of AMS at (248) 722-0262 - email Bob.Bloom@AutomaticMachiningSolutons.com.

Chris Bloom Bob Bloom

Sales Engineer General Manager

(774) 240-0014 (248) 722-0262

Bob.Bloom@automaticmachiningsolutions.com

www.automaticmachiningsolutions.com

-

_______Chris Bloom_____Bob Bloom_______

Sales Engineer General Manager